What’s the Difference Between Channel and Component Standards?

November 4, 2020 / General, 101 learning, Standard and Certification, Industrial Networks, Best Practices

When it comes to cabling standards, you’ve probably heard of channel standards and component standards. The two are not one and the same, so we thought it might make sense to explain the difference, why you should care and how they are tested.

Channel Standards

In a network, the channel is the connection from one active device to another, including any patch cords and equipment cords. In the data center, this could be from an access switch to a server and would include any patch cords used for cross-connects or interconnects between the two. In the LAN, the channel could be the connection from a distribution switch in a telecommunications room all the way to the network card in a laptop.

Based on worse-case scenario assumptions, industry standards specify the performance of a channel for a given application. For fiber, that’s primarily insertion loss. For copper, it’s quite a bit more—insertion loss, return loss, crosstalk (NEXT, FEXT, ELFEXT, ANEXT, etc.), propagation delay, DC resistance and more.

Channel standards also specify the overall length of a channel for a specific applications and cabling media. For example, standards specify that a 10GBASE-T Category 6A channel should not exceed 100 meters, and a 10BASE-SR OM4 multimode fiber channel should not exceed 400 meters.

Component Standards

Component standards refer to the standalone components that make up a channel—the cable, plugs, jacks and patch cords. For individual components, these standards specify interoperability/intermateability, mechanical requirements, physical characteristics and performance parameters such as bandwidth, frequency, insertion loss, return loss and crosstalk.

When it comes to performance, component standards are typically considered stricter than channel standards. If all components in a channel are component compliant, the channel should also be compliant—unless of course they were subjected to poor installation practices. While this doesn’t necessarily mean that non-compliant components deliver less performance, their performance cannot be guaranteed. Since there is still a good chance that a channel will meet the standard even with non-compliant components, substandard components could go unnoticed.

For example, component standards for Category 6 in a 1000BASE-T application at 100 MHz specify an insertion loss of 0.2 dB for connectors and 19.8 dB for cable, but the overall channel specifies a total insertion loss of 21.3 dB. Technically you could therefore have a channel with a Category 6 connector at 0.6 dB that does not meet the component standard, but the channel would still be compliant and support the application. However, problems arise when too many components that don’t meet component standards are used in a channel—four Category 6 connectors at 0.6 dB could push the channel insertion loss above the limit.

How Are They Tested?

Manufacturers have their individual components tested and verified to industry component standards. This is typically done through third-party testing and verification like Intertek’s ETL certification, which ensures that components meet appropriate ANSI/TIA, ISO/IEC, EN or IEEE performance standards. You’ll often see specific markings on components that indicate certification, and manufacturers claiming component standard compliance should have documentation available to prove this status.

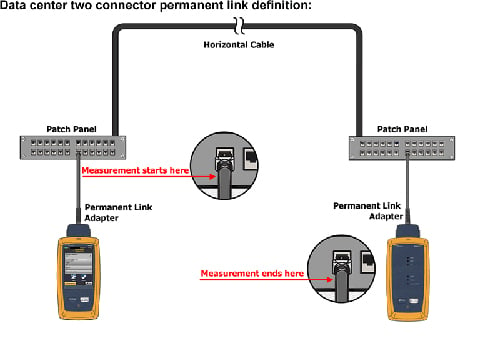

When it comes to verifying channel standards, it’s actually recommended to test the permanent link rather than the channel. The permanent link is the fixed portion of the channel that does not include patch cords and equipment cords. This is typically from patch panel to patch panel in the data center or patch panel in the telecommunications room to work area outlet or consolidation point in the LAN. If we care about channel standards to support the application, why would we only test the permanent link?

The permanent link is considered the foundation of the channel and patch cords are typically the weakest link—they are handled and replaced more than any other component and often considered a commodity, so quality (and component compliance) may be overlooked. If you test the channel, which offers more headroom than the permanent link, patch cord problems may go undetected. And if you opt for channel testing and then later swap out your patch cords, you might as well throw those channel testing results right out the window.

To achieve the absolute best channel performance and headroom on your installations, test the permanent link and choose components that meet component standards, including the patch cords. Thankfully, the permanent link adapters and test reference cords that come with the Fluke Networks’ Versiv™ family of copper and fiber certification testers and are of the highest quality to ensure interoperability and channel performance once you add those compliant patch cords.