Golden Rule of Fiber Inspection - Clean and Inspect Again

October 28, 2015 / General, 101 learning, Installation and testing, Upgrading and troubleshooting, Best Practices

Contaminated connections remain the number one cause of fiber related problems and test failures in data centers, campus and other enterprise or telecom networking environments.

And even if you think you have properly cleaned the fiber, you should always inspect every connector end-face before connecting to a component or piece of equipment—especially since the very act of cleaning can cause contamination. That’s why the golden rule is to inspect, clean and inspect again.

And even if you think you have properly cleaned the fiber, you should always inspect every connector end-face before connecting to a component or piece of equipment—especially since the very act of cleaning can cause contamination. That’s why the golden rule is to inspect, clean and inspect again.

When it comes to inspecting, there is really no way of knowing if the end-face is clean unless you use a fiber inspection tool designed specifically for that purpose, such as a professional video microscope or a handheld fiber microscope. However, as new fiber solutions and configurations continue to hit the market, it remains vital for your fiber inspection tool to keep up.

High-Density, Multi-Row MPOs

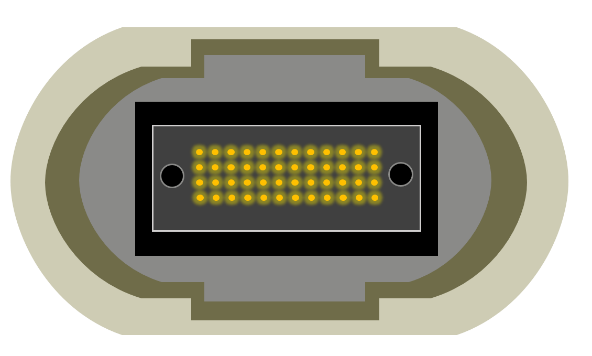

Let’s consider some of the latest ultra high-density fiber applications making their way into supercomputing data centers and outside plant applications. While most of you are likely familiar with the 12-fiber MPO connector deployed in 10, 40 and 100 gigabit fiber applications, did you know that there are also 24, 48 and 72-fiber multi-row MPO connectors being used for these high-density applications?

Multi-row MPOs are also available in singlemode angled physical contact (APC) connectors for use with higher optical wavelength ranges like those being used by service providers for RF video signals in GPON and FTTX applications.

Thankfully Fluke Networks now offers inspection tips for the FI-7000 FiberInspector™ Pro’s Versiv USB Fiber Inspection Video Probe that supports both multimode and singlemode APC multi-row MPO end faces, allowing the tip to be adjusted between rows and along the 12 fibers in a single row.

In Line with the Trends

When it comes to keeping up with fiber advancements, it’s also important to understand some of the specific vendor solutions, trends and nuances surrounding fiber connectors in the industry. That’s why Fluke Networks also now offers an extended LC bulkhead tip for connectivity solutions with deeper ports where the standard LC tip just isn’t’ long enough. Our new LC tip for patch cord inspection also now features a square cutout rather than circular to prevent turning and enable better viewing of these LC end faces.

You can rest assured that Fluke Networks will continue to keep a pulse on the latest applications and solutions to make sure you are always able to follow the golden rule of inspect, clean and inspect again—no matter what your fiber application.