What is the best Practices for Cleaning Optical Fiber

December 17, 2015 / General, 101 learning, Installation and testing, Upgrading and troubleshooting, Best Practices

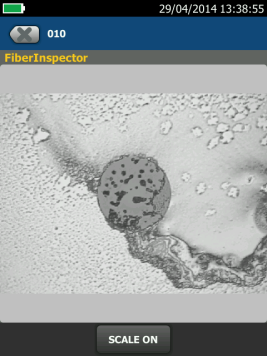

While it seems we can’t drive the point home enough that the number one cause of fiber network issues and failures is contaminated connectors, we hope by now that all fiber technicians at least know that they are SUPPOSED to clean and inspect every fiber end face before making that final connection.

But are you cleaning those fiber end faces correctly? Let’s take a look at some best practices.

Get the Right Tool for the Job

Get the Right Tool for the Job

If you’ve ever seen a technician using canned air or dusters for cleaning fiber end-faces, you’ve witnessed a very ineffective practice. Not only do canned air and dusters just succeed in blowing particles around, they are not all adequate for cleaning oils, residues, or small charged dust particles. Instead, use fabric and composite wipes made of lint-free material that provide the absorbency to remove contaminants from the end-face. But please remember to discard wipes after it’s been used up—a dirty wipe is the next dirty end face.

Yet beware of using wipes alone—often referred to as “dry cleaning”—as this can leave a static charge on the fiber end face that actually attracts statically charged dust particles. A combination of composite wipes and solvent is really the way to go—solvents boost the cleaning ability of the wipe while eliminating the issue of static charge.

And yes, even the use of solvents have a best practice when it comes to fiber cleaning. First of all, don’t use too much as it can leave behind a film, and if you do, make sure to use a new dry wipe to get rid of the excess (but not too much dry cleaning or we’re back to the static charge issue). And don’t just use any old solvent. Isopropyl alcohol can leave behind a difficult-to-remove “halo” as it dries, causing attenuation. The difference between specialized fiber cleaning solvents and what you buy at CVS is easy to see.

Specialized solvents (left) vs. isopropyl alcohol (right)

Did you know that for cleaning fiber end-faces inside ports or equipment, Fluke Networks’ offers lint-free mechanical port cleaning devices called IBC Cleaners in their fiber optic cleaning kit? They come in three different sizes for cleaning 1.5 mm, 2.5 mm and MPO style connectors. Speaking of MPO style connectors…

Beware of the Multifiber Array

Consider a multi-fiber MPO interface with an array that features a much larger surface area than a single fiber connector. Unfortunately, this larger areas makes it easier to move contaminants from one fiber to another within the same array.

And the larger the array, the higher the risk. With 24-, 48- and 72-fiber MPOs used in high-density fiber interconnects, the greater number of fibers are more difficult to control and not all the fibers always protrude at the same height. Height variances across the fibers can increase the risk of not every fiber being properly and equally cleaned.

When cleaning an MPO connector, make sure the entire end face surface touches the wipe. Apply medium pressure and wipe in a direction perpendicular to the array.

Back to Basics

While some of these may seem like the “duh” aspects of fiber cleaning, no blog on fiber cleaning best practices would be complete without these reminders.

- Never touch the fiber connector end face with your oily fingers

- Never touch the clean area of the wipe, cleaning fabric or swab

- Never touch the solvent dispensing tip

- Always were the appropriate safety glasses

- Always keep protective caps on unplugged fiber connectors

- Always store unused protective caps in a sealed connector

- Always discard used wipes immediately (can’t hurt to say that one again, can it?)

- Always follow the golden rule of cleaning

The Golden Rule?

Don’t know the golden rule of fiber cleaning? With the act of cleaning itself a potential source of contamination, the golden rule is to ALWAYS inspect, clean and inspect again. Even if you think you have properly cleaned the fiber end face, you still need to follow it.

And if you have to clean after the re-inspection; guess what? You need to inspect again.