No Remote Detected - DSP FTA Series

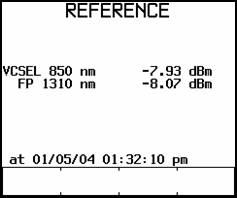

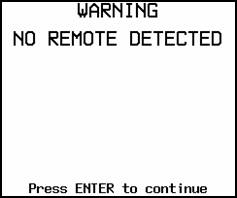

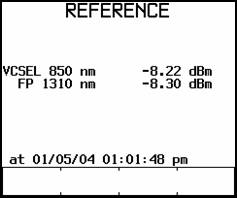

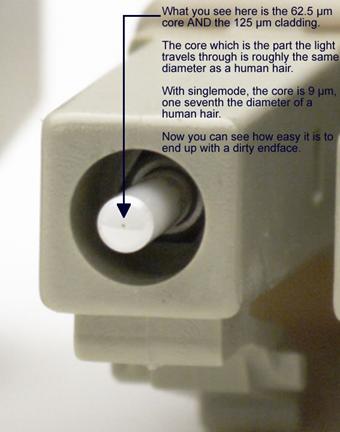

When running a fiber Autotest you may encounter the following error message:  The most obvious response is that the correct fibers are not connected. However, it is possible that they are connected correctly, and yet this message still appears. This was happening to a customer of Fluke Networks on an intermittent basis. Very frustrating indeed, so we asked him to send the adapters in for us to look at. First thing we did was to set a reference in loop back mode on one of the adapters:  The reading was reasonable. We expect between -8 dBm and -10 dBm. The same was done on the other adapter. Then we ran the units continuously without an issue. We then removed the fiber from the link under test and reconnected it. Tested it again. The reading was good. We did this on a number of occasions and eventually got the DSP-4300 to report NO REMOTE DETECTED. Using a FiberInspector and OptiFiber we inspected the end face of one of the fiber adapters. The result is shown below:  Believe it or not, there is an end face of a fiber optic connector in the photograph above. There is so much debris you cannot see it. Using Q-Tips we gently cleaned the fiber port to reveal:  Now we can see the 125 µm cladding and the 62,5 µm core. However, the debris to the left needs to be removed as this can migrate onto the core resulting in an intermittent NO REMOTE DETECTED. It does take some effort and patience to clean an adapter this dirty, but after a while we were able to achieve the following:  With this and the input port clean, we inserted the fiber back into the fiber adapter and repeated the reference measurement in loopback mode. The result is shown below:  The reading got worse! The fiber was removed and the fiber port inspected again. We found:  How can this be? Its called cross contamination. There must have been debris on the fiber patch cord which was passed onto the fiber adapter end face. A quick inspection of the fiber patch cord revealed:  Once cleaned we were able to see:  WICHTIGER HINWEIS: If the fibers you are testing are dirty, what will happen to the end faces of your test leads? They will become dirty as well and yes; NO REMOTE DETECTED. The probability of this doubles if you are doing Bi-Directional Testing. It is good practice to repeatedly clean and inspect the end faces of your test leads as you test. With ALL the adapters clean and ALL the fiber test leads clean, the reference was once again measured.

When we carried out further tests we could not repeat the NO REMOTE DETECTED error message. This is not unique to Fluke Networks Fiber Optic Testers. This applies to ALL fiber optic testers. STOP PRESS: My colleague just handed me the results of another adapter sent into the service center.  We can clean this adapter but our work is undone in an instant if a dirty patch cord is placed in the adapter. Dont even breathe on the fiber!  LC Connector with 62,5 µm multimode cable. And this is for Multimode. Lets take a quick look at Singlemode:  Can you see the small dot in the middle? This is the core, just 9 µm or roughly 1/7th the thickness of your hair. It takes little or nothing to block the light on singlemode fiber. Cleanliness becomes a real issue here. If the building is still under construction forget terminating fiber or testing it. |